Superalloy Castings

1. Product Introduction

BIAM does research in materials for making complex structures under high temperature, complex stress and corrosive environment, and their precision forming technology. It has the production line and R&D capacity for superalloy precision casting for equi-axial crystal, directional and single crystal hollow non-tolerance parts. It is the first unit in China to develop hollow directional, single crystal non-tolerance blade. It has the capacity for manufacturing advanced silicon base, aluminum base complex ceramic mold core, advanced large sized hollow non-tolerance precision castings (for instance, gas turbine blades). It has advanced inspection and testing technology for turbine blades and relevant supporting researches.

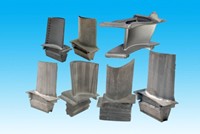

2. Main Products

|

Product Name

|

Product Type

|

|

High temperature ceramic core

|

Mold core

|

|

Integral fine crystal turbine disk

|

Equi-axial crystal integral structural components

|

|

Superalloy guider, intermediate case, etc

|

Equi-axial crystal integral structural components

|

|

Equi-axial hollow non-tolerance blade

|

Equi-axial superalloy castings

|

|

Directional columnar hollow non-tolerance blade

|

Directional superalloy castings

|

|

Single crystal solid and hollow non-tolerance blade

|

Single crystal superalloy castings

|

|

Ground turbine disk

|

Equi-axial superalloy castings

|

|

Standard femoral condyle

|

Casting artificial joint

|

|

|

|

|

Superalloy turbine disk castings

|

Superalloy guider, intermediate case castings

|

|

|

|

|

Equi-axial crystal hollow blade

|

Directional solidification hollow blade

|

|

|

|

|

Ground gas turbine blade

|

Casting artificial joint

|